Sistema di Visione Yamaha iVY2+

RCX320/340 CONTROLLER YAMAHA ROBOT VISION

iVY2+ SYSTEM

Sistema di Visione Integrato con modalità “plug-and-play”

Il sistema di visione Yamaha IVY2+ è completamente sviluppato da casa madre e per questo motivo è integrato perfettamente con i software di programmazione dei robots senza necessità di scrivere codice per l’integrazione

- Controllers supportati: RCX320・RCX340

- Numero di pixel dello schermo: 400,000 pixels / 1,600,000 pixels / 3,200,000 pixels / 5,000,000 pixels

- Capacità di impostazione del modello: 254 modelli

iVY2+ Facile da usare, semplici comandi per la programmazione

Semplicità

La configurazione viene completata effettuata in otto minuti dopo l’accensione e la calibrazione automatica semplifica la configurazione.

Precisione

Con un massimo di cinque milioni di pixel, è possibile supportare una varietà di aree di lavoro. Migliora la produttività fino a 100 Colpo Per Minuto con la funzione conveyor tracking.

Affidabilità

Le procedure guidate comprendono tutto il processo, dall’acquisizione dell’immagine della telecamera al funzionamento della pinza e del robot. Non servono complesse procedure di programmazione, tutto è semplificato.

Caratteristiche

Rilevazione ad alta velocità di forme irregolari (ad. es cibo o vestiti) NEW

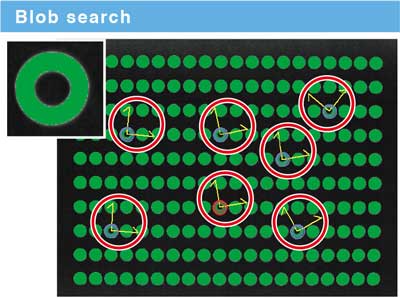

Funzione di ricerca Blob

Adatto alla rilevazione di pezzi dalle forme irregolari o per il conteggio ad alta velocità.

Con questa modalità la velocità di acquisizione è fino a 10 volte più rapida rispetto alla rilevazione di precisione.

Il tempo di acquisizione è stato ridotto del 45% NEW

Grazie all’utilizzo di nuove telecamere ad alte prestazioni e all’incremento della potenza di calcolo della CPU, il tempo di acquisizione è stato ridotto dall’ 8 al 45% con un aumento delle performance in termini di risoluzione.

Confronto dei tempi di acquisizione

Adatto alla rilevazione di alte cadenze ed al conteggio di grandi volumi NEW

Rilevazione di componenti elettronici

Rilevazione di accessori in un kit

Conteggio del numero di bottiglie

Rilevazione di etichette

Rilevazione di viti e rondelle

Verifica di presenza fori

Conteggio di componenti elettronici

Gestione di pezzi sovrapposti NEW

I pezzi sovrapposti possono essere riconosciuti ed esclusi dal processo di identificazione.

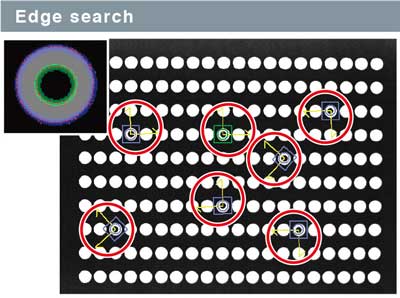

Velocità di acquisizione NEW

Rispetto alla ricerca dei profili, la ricerca di tipo “blob” risulta fino a 10 volte più rapida.

Paragone della velocità di acquisizione in modalità Profilo o Blob

Scheda di acquisizione integrata del controller robot

Setup tipico di un sistema tradizionale

- Laboriosi tempi di allineamento coordinate robot-camera

- Necessità di calcoli di compensazione in caso di telecamera mobile

- Correzioni da effettuare a causa del ritardo di comunicazione visione-robot

- Studio ed implementazione dei protocolli di scambio dati

Sistema di visione Yamaha RCXiVY2+

- Procedura semplificata di calibrazione incorporata

- Le coordinate vengono corrette in automatico in caso di camera mobile

- Connessione ad alta velocità su bus interno dedicato

- Controller incorporato per avere un unico sistema di sviluppo

- Protocollo già integrato nei comandi specifici Yamaha

Esempi di programmazione

【VSEARCH】Detect parts with designated camera

Camera and component type to be used for detection and the calibration data to be used can be switched with one command.

【VGETPOS】Acquires the coordinates of the detected workpieces.

The search results can be substituted into the point coordinates directly.

【LVOLUME】Intensity of light is adjustable from 0 to 100% range

In detection mode intensity of light can be adjusted with one command.

Detection can be repeated with adjusted intensity.

Tempo di start-up ridotto

3 semplici passi per la registrazione dei modelli

Partendo dalla fotografia del pezzo, la memorizzazione del pezzo richiede solo 3 passi.

Processo di rilevazione rapido e comprensibile

Esempio di utilizzo dello strumento “penna”

Quando è necessario distinguere pezzi diversi oppure il fronte/retro è necessario colorare i contorni dei diversi pezzi per insegnare al sistema ciò che è valido da ciò che serve scartare. Diversi colori indicano aree prioritarie da analizzare.

Calibrazione semplice

I sistemi di visione tradizionali richiedono molto tempo per la calibrazione che serve per adattare le coordinate della telecamera rispetto alle coordinate del robot. Con il sistema RCXiVY2+ sarà sufficiente seguire una procedura guidata che porterà a termine la calibrazione in pochi minuti.

Calibrazione effettuata con un utensile Yamaha

Una calibrazione accurata ed ottimale si può ottenere in modo automatico utilizzando l’utensile di calibrazione Yamaha senza quindi dipendere dalle abilità del programmatore. Dal momento che questo utensile è una parte standard Yamaha, il cliente non deve preoccuparsi di produrre utensili di calibrazione. Tutto è già pronto all’uso.

Tempi di programmazione ridotti al minimo

Quando si utilizzano sistemi di visione di terze parti è necessario effettuare delle conversioni di coordinate perchè spesso i formati in cui vengono espresse le coordinate robot-visione non sono uniformi.

RCXiVY2+, il sistema di visione è incorporato nel controller e ne condivide i dati. Ciò semplifica notevolmente i processi di programmazione perchè tutti i controlli sulla telecamera ed anche sugli illuminatori possono essere effettuati nel programma del robot. Le procedure di programmazione sono quindi ridotti ai minimi termini.

Paragone dei tempi di setup

Semplice connessione dei componenti

Un unico controller concentra la gestione di robot, telecamera, illuminatore e gripper.

Configurazione tipica del sistema

Usabilità

Ambiente di programmazione semplificato RCXiVY2+ Studio

Il software di programmazione “RCXiVY2+ Studio” è possibile effettuare tutte le operazioni necessarie come la registrazione dei pezzi campione, la definizione dei contorni, i parametri della telecamera, backup e restore nonchè utili funzioni di monitor in tempo reale.

Acquisizione di trial e registrazione della parte

Registrazione dei pezzi campione (per la calibrazione)

Fino a 254 modelli diversi memorizzabili

Facile aggiunta di nuovi modelli

Il sistema può riconoscere fino a 100 pezzi contemporaneamente

Salvataggio dati

Funzioni di monitor realtime anche durante la programmazione

Programmazione semplificata

Grazie alle procedure guidate ed agli esempi di programmazione forniti da Yamaha il programma viene creato automaticamente seguendo i passi suggeriti dal software RCX-Studio 2020:

Pick&Place da pallet con sistema di visione

Deposizione sigillante con ausilio di telecamera

Correzione della posizione del gripper con sistema di visione

Il sistema di visione Yamaha è compatibile con tutta la gamma di robot e assi lineari così da poter selezionare la migliore soluzione per le applicazioni richieste

XY-X Robots cartesiani

YK-XG/XE Robots Scara

YK-TW Robots orbitali

FLIP-X Assi lineari

Fino a 254 modelli memorizzabili

E’ sufficiente selezionare il modello per regolare tutte le impostazioni automaticamente.

Ricerca di alta precisione anche in scarse condizioni di luminosità

Algoritmo di ricerca profili integrato

Adatto ad una grande varietà di applicazioni anche in condizioni gravose

Condizioni di luminosità ottimali

Ricerca accurata anche in scarse condizioni di luminosità

Monitor output

Monitor per le condizioni operative

Una funzione dedicata permette il monitoraggio in tempo reale delle immagini ed impostazioni

Tipi di dati visualizzati

- Modello selezionato / Immagine registrata

- Risultati dell’acquisizione (posizione, punteggio, scala)

- Comando eseguito

- Tempo richiesto per l’acquisizione

Formato dell’uscita

- DVI-I (supporta digital monitor e analog monitor)

Funzioni di correzione della distorsione delle lenti e dell’inclinazione della telecamera

Uno speciale algoritmo permette di correggere i problemi tipici di distorsione dell’immagine dovuti all’utilizzo di lenti nonchè di compensare l’inclinazione della telecamera che può avvenire in fase di montaggio ed installazione.

Tali correzioni vengono effettuate in fase di calibrazione.

Supporto di applicazioni con telecamera mobile

Nel caso in cui la telecamera viene montata direttamente sul robot, le coordinate vengono automaticamente convertite rispetto alla posizione del robot stesso.

Se la telecamera è montata sul robot, le coordinate vengono automaticamente convertite rispetto ai movimenti del robot stesso.

Conveyor tracking

Grazie a questa funzione è possibile collegare un encoder al sistema di visione per fare in modo che il robot possa “inseguire” il pezzo da prendere che ad esempio potrebbe essere su un nastro trasportatore in movimento. In tal modo è possibile effettuare applicazioni ad alta cadenza senza fermare i pezzi che devono essere presi dal robot stesso.

Possibilità di controllo multi-robot da un unico controller master

Verifica dell’applicazione in fase di pre-vendita

Il nostro servizio effettua gratuitamente lo studio dell’applicazione basandosi su campioni forniti dal cliente.

Sulla base dei risultati ottenuti verrà generata la miglior offerta economica per soddisfare le esigenze del cliente.

Specifiche Tecniche

| Robot vision basic specifications | RCXiVY2+ unit |

|---|---|

| Number of screen pixels | 728(H) × 544(V) (400,000 pixels) 1456(H) × 1088(V) (1,600,000 pixels) 2048(H) × 1536(V) (3,200,000 pixels) 2592(H) × 1944(V) (5,000,000 pixels) * |

| Model setting capacity | 254 models |

| Number of connectable cameras | 2 cameras |

| Connectable camera | GigE camera PoE: IEEE802.3af 1 ch up to 7W |

| External interface | Ethernet (1000BASE-T) ** USB 2.0 2Ch (Up to 5V 2.5W / ch) *** |

| External monitor output | DVI-I **** Monitor resolution: 1024 × 768 Vertical periodic frequency: 60 Hz Horizontal periodic frequency: 48.4 kHz |

| Power supply | 24 VDC +/-10%, Maximum 1.5 A |

| Dimensions | W45 × H195 × D130 (RCXiVY2+ unit only) |

| Weight | 0.8kg (RCXiVY2+ unit only, when the lighting control board option is selected) |

| Operating environment | Compliant with the RCX340/RCX320 controller. |

| Storage environment | Compliant with the RCX340/RCX320 controller. |

| Search method | Edge search (correlated edge filter, sobel filter), Measurement function, Blob search |

| Image capturing Trigger mode | S/W trigger, H/W trigger |

| Image capturing External trigger input | 2 points |

| Function | Position detection, coordinate conversion, automatic point data generation, distortion and inclination correction |

| Camera installation position | Fixed to the fixed camera (up, down) or robot (Y-axis, Z-axis). Perpendicular to the workpiece to be captured. |

| Setting support function | Calibration, image save function, model registration *****, fiducial mark registration *****, measurement function registration *****, blob registration *****, monitor function ***** |

| Number of connectable lighting units | Maximum 2 |

| Modulated light format | PWM modulated light control (0 to 100%), PWM frequency switchable 62.5 kHz/ 125 kHz Continuous light, strobe light (follows camera exposure) |

| Lighting output | 12VDC or 24VDC (external supply shared by both channels) |

| Lighting output | For 12VDC supply: Total of less than 40W for both channels. For 24VDC supply: Total of less than 80W for both channels. |

* Since the rolling shutter is used, the tracking is not supported.

** For setting and monitor operations

*** It is planned to support this USB later.

**** Also usable with an analog monitor by using a conversion adaptor.

***** RCXiVY2+ Studio function (requires a Windows PC)

| Tracking board basic specifications | Tracking board |

|---|---|

| Applicable controllers | RCX340/RCX320 |

| Number of connected encoders | Up to 2 units |

| Encoder power supply | 5VDC (2 counters total 500 mA or less) (Supplied from controller) |

| Applicable encoder | 26LS31/26C31 or equivalent line driver (RS-422 compliance) |

| Input phase | A, A, B, B, Z, Z |

| Max. response frequency | 2MHz or less |

| Counter | 0 to 65535 |

| Multiplier | 4x |

| Other | With disconnection detection function |

External view

RCX340 + RCXiVY2+

RCX320 + RCXiVY2+